Reduce your costs and increase the service life of the rollers. When in a new condition, carbide and tool steel rollers generally have a diameter that allows them to be reconditioned on multiple occasions. The service life is tripled / quadrupled as a result.

Rollers that come to our specialist facility for reconditioning are examined for defective bearing seats as well as further damages, recorded and are given a sequence number for further internal processing and monitoring if not already present.

After these production processes have been completed, the rollers are carefully reconditioned with the desired possible dimensions We will inform you in good time should further improvements be required.

The Suski Drahtwalzwerkzeuge Company also offers the following services in addition to the grinding of carbide rollers:

- Reconditioning of carbide rollers

- Manufacturing of carbide rollers

- Regrinding of carbide rollers

- Shell refinement for carbide rollers

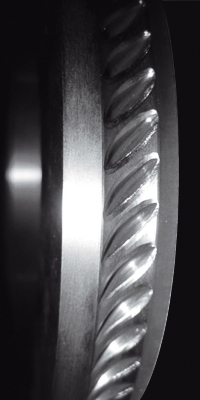

Examples of carbide rollers in a worn condition and once they have been professionally repaired for customers from the wire industry by us. The traces of wear on the carbide rollers can be seen clearly on the photos. You can already see profile failures in the photo on the left.

These carbide rollers for ribbed steels in the wire industry (e.g. for concrete steel / reinforced steel) have been carefully reconditioned by our specialist facility for wire rolling tools in the possible dimension as desired by the customer and they will continue to provide excellent service in the rolling stands for long products.