Repaired Better

You would like to overhaul your machines and rollers yet require quality and service at the same time?

Then know-how is needed. We work together with specialists and experts from various trades in order to guarantee you the best possible quality. Our trained team comprises of mechanical engineers, electricians and technicians who work with the aim of offering the best possible quality and flexibility. We offer you machines that function flawlessly and sometimes even in excess of this thanks to the latest technology from one single source. Our quality and low prices form the standard with which we allow ourselves to be measured by you.

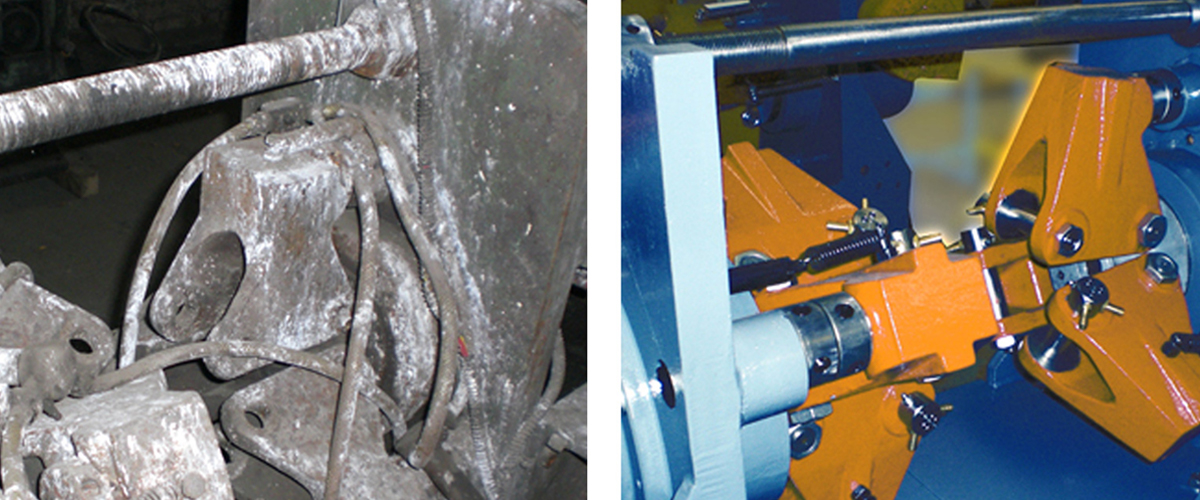

First the pre-owned machines are disassembled into individual pieces by our team and are then subjected to an exact visual and mechanical examination.

It goes without saying that worn parts such as bearings, valves, guides, seals, etc. are replaced by new parts. In doing so, the thorough cost-benefit analysis is decisive.

The entire machine frame is subjected to a thorough clean and examination. The frame is given a new coat and repaired where necessary.

After the most thorough of examinations has been completed, the covering hoods, magnetic fuse switch and the machine-related covers are repaired or replaced – in accordance with the conditions of the employer’s liability insurance association – in order to meet each and every one of the safety requirements. Electric motors and control elements are examined and are replaced by new parts in the event of defects.

We are more than happy to manufacture customer-specific special requirements by arrangement.

The compact rolling device is a rolling device for TRIO design carbide rollers

This compact rolling device is ideal for smooth and ribbed wires in the wire rod finishing area up to 16 mm in diameter, max. inlet 18 mm diameters, maximum cross-section acceptance of 30%. Carbide rollers and tool steel rollers with diameters of up to 150 mm can be used. The bearing retainers are suitable for bearings 65 mm wide with ø 90 mm roller retainers. It possesses a central, motorised supply of the rollers manufactured from carbide or other materials and is delivered complete with zero value counter and cooling bolts but without rollers and bearings.

Carbide roller repair

Reduce your costs and increase the service life of the rollers.

When in a new condition, carbide and tool steel rollers generally have a diameter that allows them to be reconditioned on multiple occasions. The service life is tripled / quadrupled as a result.

Read On